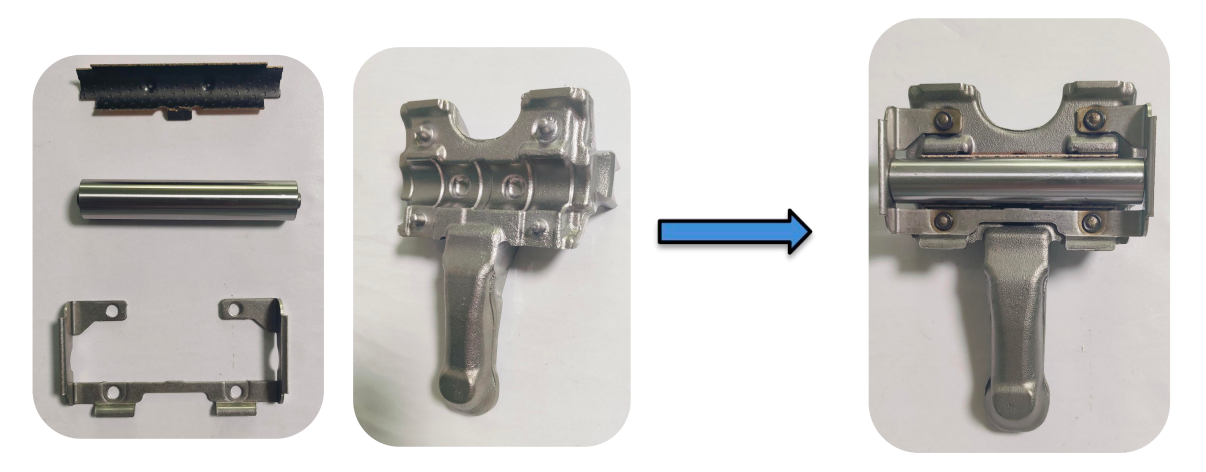

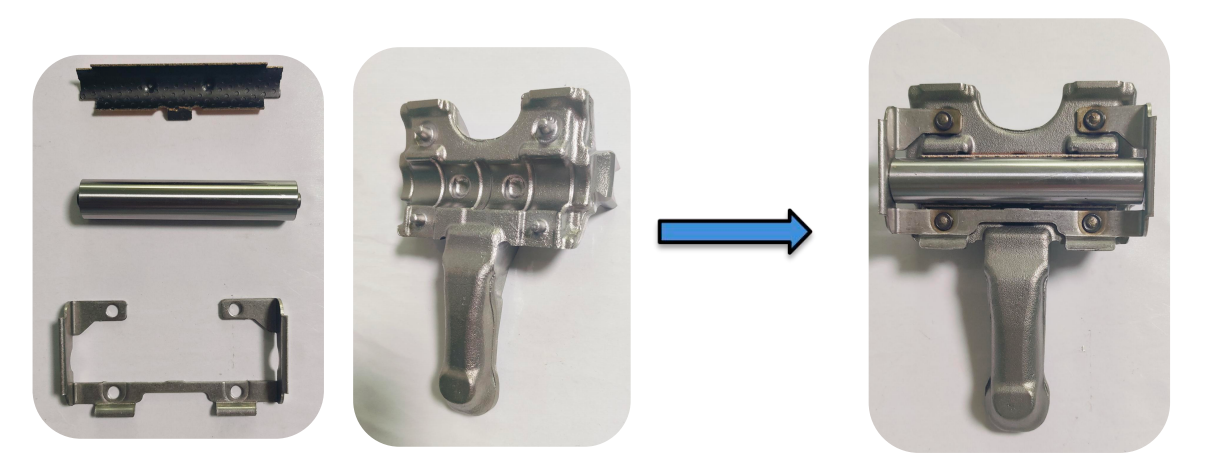

Core components for pneumatic disc brakes -Brake lever

Advantages:

1.Independent design and mold manufacturing capabilities have reduced the new product development cycle from the previous 40 days to just 20 days.

2.In-house forging, heat treatment, and cold extrusion production lines enable self-sufficiency, accelerating delivery cycles and reducing safety stock.

3.Breakthroughs in precision forging technology enhance product quality, optimize processes, reduce costs, and improve efficiency.

4.Monthly production capacity: 50,000 sets.

1.Material: 16MnCr5 or 20CrMnTIH

2.Heat Treatment Process: Carburizing

3.Key Control Points: R9 inner circle, R27.5 outer circle, fork, R8.5 ball socket, hot riveting assembly

4.Data Affected by the Lever in ADB:

- Lever ratio

- Brake clearance

5.Common Issues with the Lever:

- Cage fracture

- Wear-resistant layer of the bushing prone to peeling

- Fork fracture

6.The cage is made of Baosteel HC750 material to enhance strength and prevent fracture.

7.The lever has undergone customer testing, including bench tests, inertia tests, high and low-temperature tests, vibration tests, and torsional fatigue tests (1.0 MPa air pressure) for 600,000 cycles without damage.

Adjusting Mechanism Assembly

Caliper Adjuster Mechanism

.webp)